Rebuilt Toyota 22re Engine

The Toyota 22re engine comes from Toyota Corporation R engine family which power some of most famous Toyota vehicles in history...

Such as the 1981 to 1984 straight axle 4x4 pickup trucks, 1987 Toyota 4runner, Celica, and Toyota Tacoma. These vehicles were designed for the 22re longitudinal engine placement. Most of these vehicles came in 5 speed transmissions, which was great for performance upgrades.

About The 22re

The Toyota 22re engine appeared on the scene in 1982 with dome pistons with a recess in the center of the piston. These were also tall deck blocks with 11.280 deck height duel row timing chain, also they came with hemispherical combustion chamber. In 1985 they redesigned the Toyota 22re completely, first they reduce the deck height to 11.080, the piston design went to a flat top piston with two valve reliefs. The stock 22re horsepower output 113 hp × 140 lb-ft of torque at 3,600 rpm, this is a long stroke engine which why torque starts building fast in the low rpm range. Also with this new redesigned 22re oil pump, water pump, timing cover and pistons can not interchange with early blocks. Next the timing setup was changed from the duel row timing set to a single row timing set to reduce the chain drag, the after market came out with the steel timing guide so would chain wouldn't eat through timing cover which causes a the oil and antifreeze to mix, which can be miss diagnosed as a head gasket failure, which leads to engine over heating, main and rod bearings washing out leading to a knocking sound in the engine.

The Toyota 22re engine has been the workhorse Toyota pickup trucks and Toyota cars. Created for low bottom end torque and longevity these 22re engines are bullet proof. First these engines come with a high-quality forged crankshaft which are built for abuse, next the wristpins are free floating which are great for oil lubrication next the connecting rods are forged too great for that low bottom end stress. The Toyota 22re cylinder head is made of aluminum which can dissipate heat at a fast rate, the combustion chamber is a swirl induce chamber design. The pistons in these factory Toyota engines are cast in design, great for weight reduction on the rotating assembly enabling the engine rev up pretty fast.

Meant To Last...

The Toyota pickup trucks powered with a 22re engine has a big following in the hunting community. They use them to go down in woods to hunt, bring out a prize catch or use to reach that prized fishing hole, or just some serious 4x4 back trails. With the price of gas at an all time high these Toyota pickup trucks are moving back to becoming daily drivers. These trucks and 22re engines were meant to last. The average life span of a 22r/22re engine is between 200,000 to 400,000 miles and some even reach 600,000 miles! In 1985, Toyota created the turbocharged 22R-TE to power the Toyota 4runner and Toyota pickup truck. The power output for this engine produced 135 hp at 4800 rpm and 173 lb-ft at 2800 rpm.

The aftermarket used this factory turbo layout to build more powerful turbo systems that generate horsepower past 200 hp! As with anything, nothing can last forever, not even the legendary Toyota22re engine. You need somebody that specializes in building Toyota engines. Motor 1 Engines builds 22r / 22re carburetor or fuel injection engines. We specialize in building 22re long blocks, 22re short blocks and 22re crate engines. We are a full machine shop with all the tooling to produce top quality 22re engines.

Build Process

How We Build The 22re

We have been building Toyota engines since 1990. Our build process is multi-step to insure that you get a great engine for your Toyota pick-up or car.

1st Step: We take a Toyota 22re block and hot tank it and pressure wash it .we also clean out the oil galleries with brushes.

2nd Step: We start with a Toyota 22r /22re factory block, which we check for cracks using a Magnaflux coil wrap machine in which a coil is wrap around the block to locate cracks. Using a magnetic field created by the coil wrap.

3rd Step: We tap and chase bolt holes so they will hold the correct torque.

4th Step: We machine the main cap outside surface, so when oil makes contact with the caps machine smooth surface the can return faster back to the oil pan.

5th Step: We machine the big end of the connecting rods.

6th Step: We press out and press in new wrist pin bushings, then we hone each wrist pin bushing to fit the new wrist pin.

7th Step: We bore the cylinder to fit the piston.

8th Step: We hone the cylinder to fit the piston ,then we let the cylinder cool over night, then do finally hone.

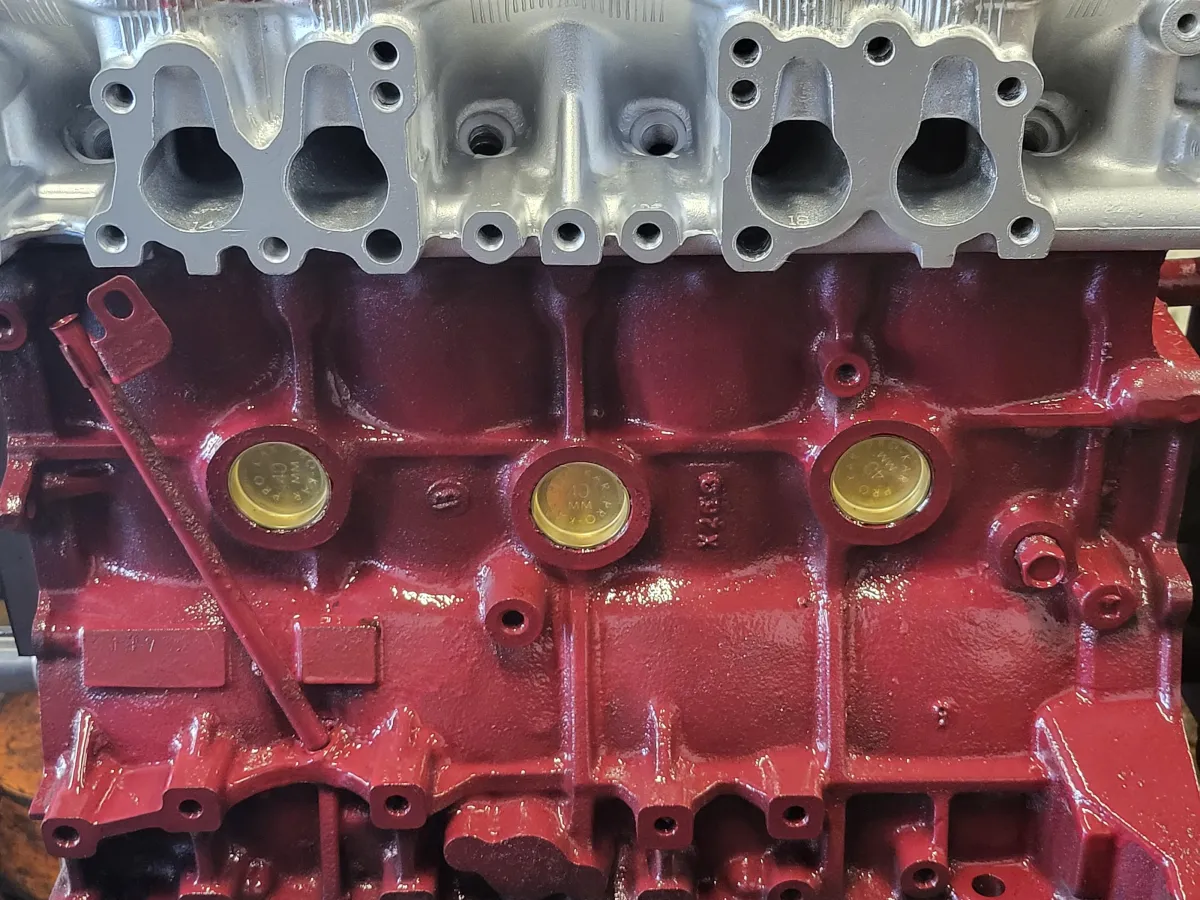

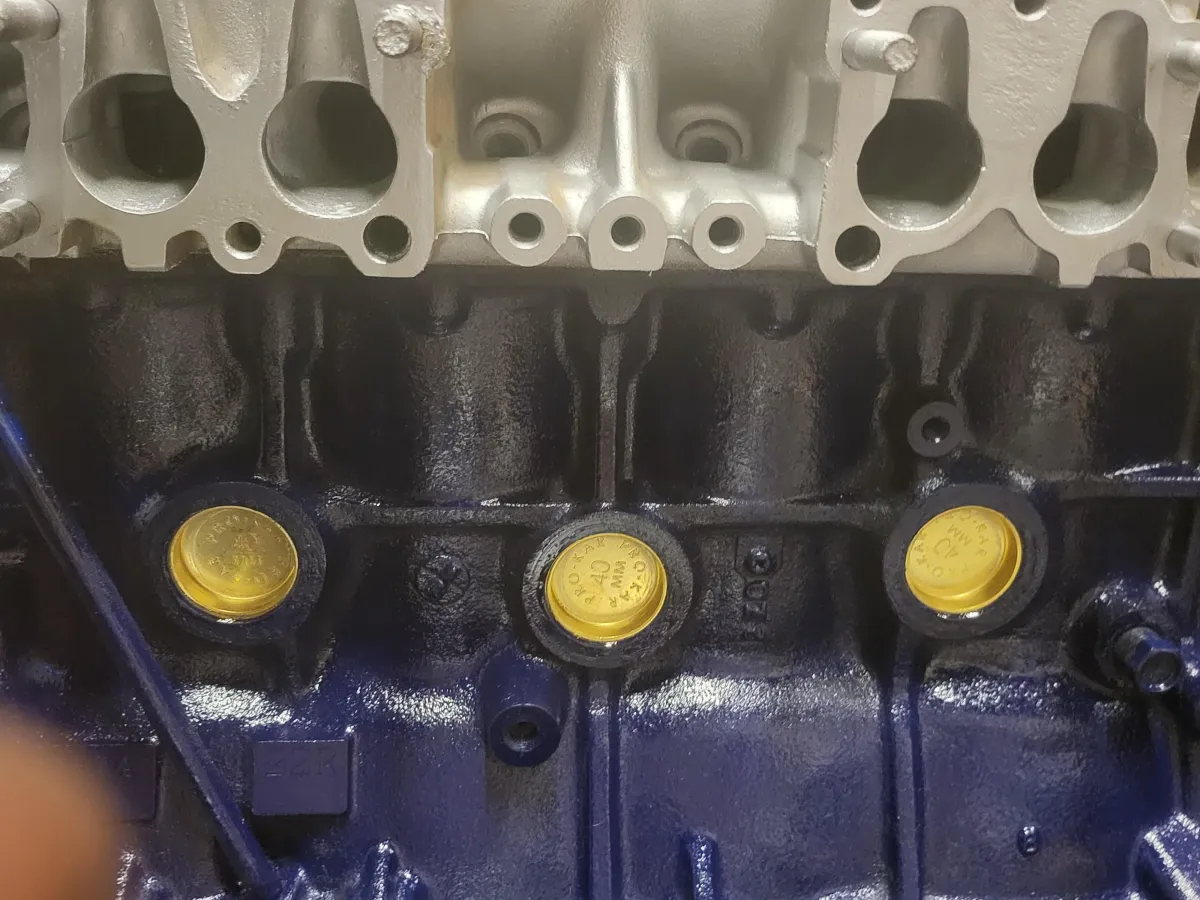

9th Step: We polish the freeze plug opening, then install aircraft sealant.

10th Step: We install brass freeze plugs.

11th Step: We machine the head and mill the head flat, then we go in and polish the combustion chamber.

12th Step: We do a three angle valve job on the seats.

13th Step: We do is grind the valves.

14th Step: We install new valve stem seals.

15th Step: We install steel or molly rings.

16th Step: We Install new main bearings.

17th Step: We install new rod bearings.

18th Step: We install brand new freeze plugs.

19th Step: We paint the block.

20th Step: We install the new timing set with metal guides.

21st Step: We simtest each engine for oil pressure, oil flow through out the block, compression in each cylinder, pre ring break in and timing.

Here at Motor 1 Engines We Speak Toyota

We have hundreds of satisfied 22re customers. If you need you Toyota 22re engine built for your stock daily driver we got you covered, you need 22re longblock for your trail rig, we got you covered, need a hi-performance or race build we got you covered. Call today and see how can we can you and you 22re back on the road.

919.857.5707

For All Your Rebuilt Engine Needs

Address

120 Centrewest Court Suite 112,

Cary, NC 27513

info@motor1engines.com

Phone

919.857.5707

Copyright 2023. Motor1Engines. All rights reserved.