Rebuilt Toyota 3.0 v6 Engine

The Toyota corporation brought the Toyota 3vze 3.0l V6 engine to the market place in 1988.

They produce the 3vze engine go in there 2 wheel and 4 wheel drive pickups, 4runners, t100 and commercial vehicles such as the U-Haul box truck. When Toyota Corporation built the 3vze engine they base it on a 60 degree cast iron block with a 2958cc displacement, which creates a 3.0l v6 engine.

About the Toyota 3.0I v6 Engine

The 3vze comes with flat top pistons from the factory with a compression ratio of 9 to 1. The first 3vze engines that came out in 1988 to 1992 came with a spring loaded tensioner which are located in the engineblock. As the production of the engine progress, the tensioner design changed to a hydraulic tensioner that is located in the right cylinderhead. The cylinderheads are SOHC 8 valve single overhead cam bucket shim aluminum heads. The power output for this engine when it first came out in 1988 was 145hp x 4800 rpm, then later to 150hp x 4800 rpms and the torque output increased to 180 lb-ft x 3400 rpm.

Build Process

How We Build The 3.0I v6 Engine

We have been building Toyota engines since 1990. Our build process is multi-step to insure that you get a great engine for your Toyota pick-up or car.

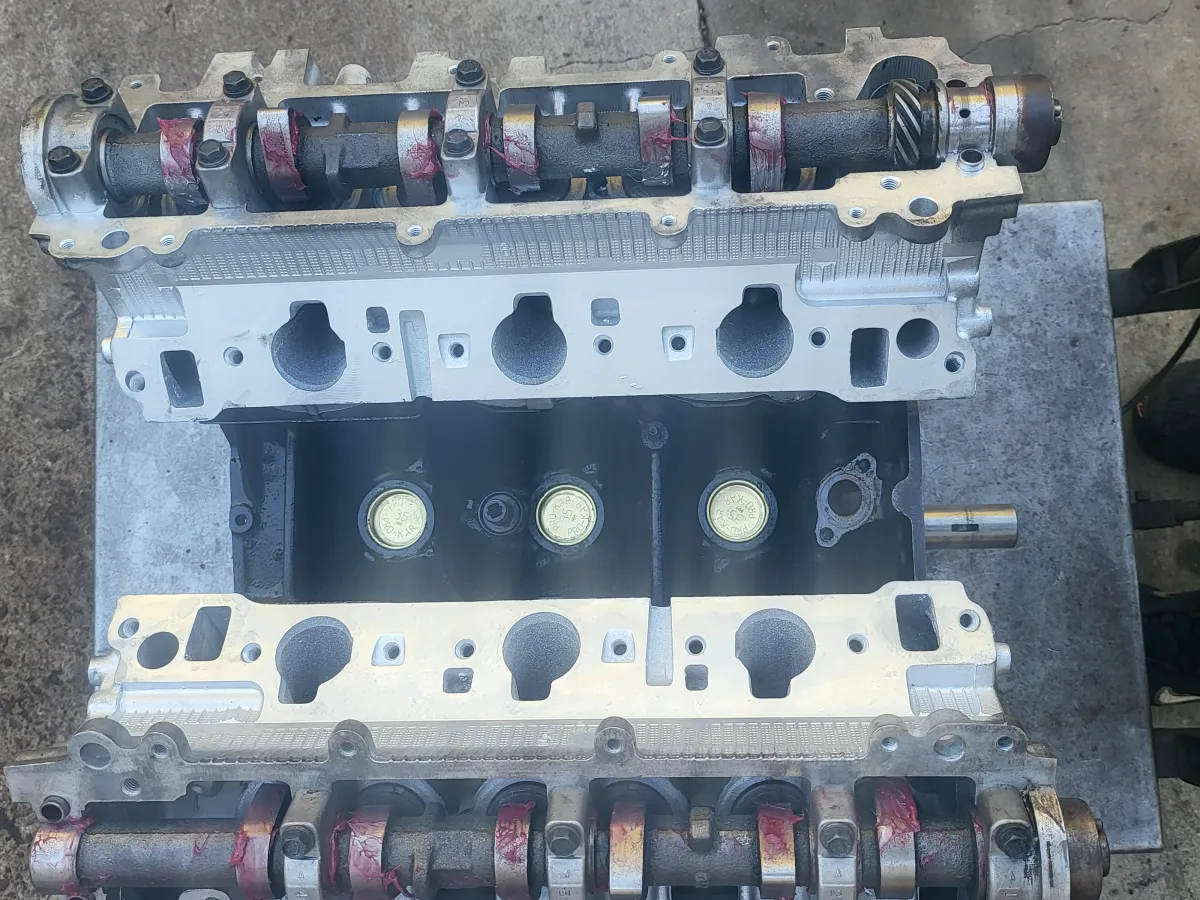

Rebuilt Toyota 3vze 3.0I Long Block Engine

Our long block Toyota 3vze v6 engines come with a 2year/24,000 mile warranty.

1st Step: start with a factory Toyota original block hot tank the block, remove all the expansion plugs, Magnaflux the block for cracks, clean and inspect. Then the pan rails of the block, the front of the block and the deck of the block are all machine to remove all the rust.

2nd Step: bore each cylinder to new piston size.

3rd Step: hone each cylinder with a 280 grit that develops the a great cross hatch for keeping oil on the cylinder wall.

4th Step: press on new pistons and wrist pins.

5th Step: connecting rod big end is resized on the big end.

6th Step: crankshaft is polish or turned to the next bearing size.

7th Step: when all the machine work in completed on the block it is washed, compressed air dried, then painted with brass freeze plugs installed.

8th Step: aftermarket main bearing are installed in the block with the thrust washers.

9th Step: the crankshaft is installed with the main caps.

10th Step: compression rings, oil rings, oil scraper rings are installed on the pistons.

11th Step: the pistons and connecting are installed in 3vze engine block. All of the bearing surface are coated in engine lube.

12th Step: the cylinderhead is disassembled, hot tanked and pressured tested.

13th Step: valve seats are inspected and replaced if needed.

14th Step: the Toyota factory valves are clean and ground to a 3 angle valve job.

15th Step: We check the valve guides and replace as needed.

16t Step: we clean the camshaft inspect and measure the cam lobes and then we polish the camshaft.

17th Step: we adjust the shim and the buckets by grinding the valve or stem.

18th Step: we install the head on the block with new head bolts ,then we torque to the correct torque to each head bolt.

Rebuilt Toyota 3vze Short Block Engine

The short block comes with a 6 month warranty. You must return a core in order to get a engine. When we finish building your engine, you return the core either through shipping or dropping the core off when picking up your engine at our shop. See "Rebuildable Core Qualifications" for more information.

1st Step: Toyota 3vze block is hot tanked, wired brushed, and powered washed.

2nd Step: Toyota block is Magnaflux coiled wrapped to check for cracks.

3rd Step: block is bored out with a van norman boring bar.

4th Step: block is hone out with a Rottler honing machine.

5th Step: Toyota connecting rod big end resized.

6th Step: new pistons are pressed on the reconditioned connecting rod.

7th Step: new compression ring, oil ring, and oil scraper rings install on each piston.

8th Step: the crankshaft is ground and polished.

9th Step: the reconditioned Toyota crankshaft is installed in the block with bearing lubed.

10th Step: the pistons and connecting rods are installed in the block.

11th Step: the short block is simtested for oil pressure and pre breaking the rings.

Rebuildable Core Qualifications

No holes or cracks in the block.

The crankshaft must be rebuildable.

The connecting rods must be rebuildable.

The cylinderhead must be able to be resurface.

Rocker arm assembly complete.

The engine bores nothing over 0.30 thousands.

Custom Built Toyota 3vze Engines

We can build custom built Toyota 3vze engines, here are some of the upgrade options:

Heavy duty 3vze aftermarket cylinderheads with the thicker casting walls.

Multilayer head gasket for high compression and turbocharging applications.

Forged pistons for high-performance turbo or nitrous applications

Head stud bolts custom built.

Gasket port match create better air flow, which means more horsepower.

Total seal rings creates less blow by.

We Build Engines To The Customer's Driving Habits

We ask a series of questions before we build your engine so you get a quality engine build that you can be proud of and keep your truck on the road for many more years of service. Call today and see how can we can get your engine back on the road.

919.857.5707

For All Your Rebuilt Engine Needs

Address

120 Centrewest Court Suite 112,

Cary, NC 27513

info@motor1engines.com

Phone

919.857.5707

Copyright 2023. Motor1Engines. All rights reserved.